Best Jaw Coupling Manufacturer

What Is Flexible Jaw Coupling?

The jaw coupling is a versatile and reliable mechanical coupling. They are widely used in power transmission applications. The benefits of using these couplings include good damping and shock absorption capabilities, as well as the ability to transmit torque.

Flexible jaw couplings can be made from a variety of materials including steel, aluminum, bronze and stainless steel. Plus, they have a wide range of torque capacities and are able to handle misalignment.

When selecting a jaw coupling, consider its design. Some of the more common designs have a solid star configuration, while others have curved joint faces. This allows for easier assembly of components. In addition, the spider can be replaced without replacing the entire jaw.

Depending on the application, the elastic jaw couplings can also be equipped with a special zero-backlash design. This design uses slightly rounded teeth in the spider to prevent kickback.

The Advantage of the Flexible Jaw Coupling

Jaw couplings have many advantages over other types of couplings. The advantage of the flexible jaw coupling is low cost, easy installation, good speed capability and fail-safe design. They are also suitable for applications where vibration must be kept to a minimum.

Choosing the right elastic coupling can ensure you reduced noise and long-term maintenance costs. It is important to understand how they work in order to choose the right one for your application. Once you understand their functions, choosing the right one is not difficult.

In general, there are four main types of aluminum jaw coupling couplings. They include grid couplings, chain couplings, slider couplings and jaw couplings. Each has its own unique characteristics and characteristics. The type of coupling you choose depends on your application, backlash, torque and misalignment allowance. Using the wrong shaft can cause a variety of problems including shaft fretting, wear and noise.

About Us

EVER-POWER GROUP CO., LTD. IS SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS’ DRAWINGS.

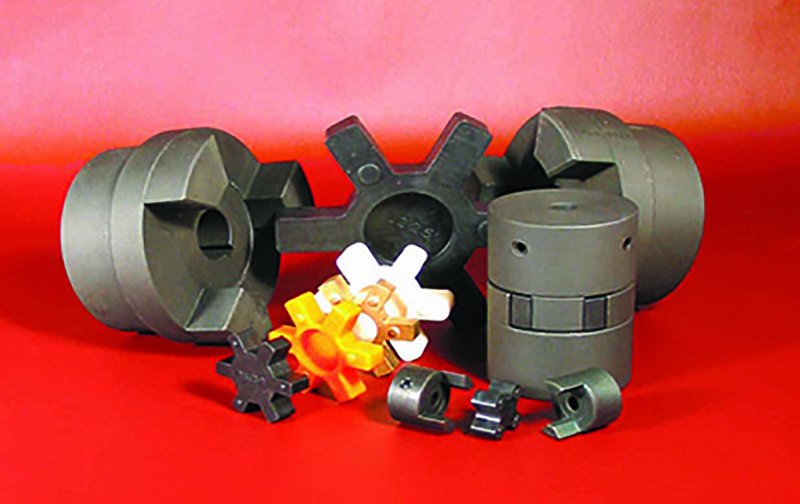

Curved Jaw Couplings

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for a higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments. The hubs are produced from a variety of materials including; aluminum, gray iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

Jaw Couplings

A jaw coupling is a type of coupling designed to transmit torque while damping system vibrations, which protects other components from damage. Jaw couplings are considered the most popular couplings utilized in industry for relatively small shaft sizes. Jaw couplings are composed of three parts: two metallic hubs and a insert, which is referred to as a “spider.” The three parts press fit together with a jaw from each hub fitted alternately with the lobes of the spider. The curved jaws of the hubs reduce deformation of the spider to maintain the zero backlash fit. It is important to note that most manufacturers sell the components of a jaw coupling separately. Most applications will require the hubs to have different bore sizes, as the shafts are unlikely to be the same size.

Jaw Coupling UFC Series

Jaw Couplings require no lubrication and provide high reliability for light to medium duty applications with good alignment of equipment and no requirement for torsional dampening.

In normal operating conditions there is no metal to metal contact so the life of the jaw coupling hubs is virtually indefinite. However, in a catastrophic failure of the element the load would still be carried by the hubs providing a degree of failure protection.

The standard element material is NBR (N)-‘Synthetic Rubber’. It is highly flexible, oil resistant and the torsionally softest of the element options. It has a temperature operating range suitable for most industrial applications and allows for up to 1 degree misalignment capacity of the connected shafts. NBR is the most economically priced option.

Jaw Coupling Parts

As jaw coupling manufacturers, we will do our best to serve you. If you need customized products, or the products you need are not found in our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, we will reply you within 24 hours!

Jaw Coupling Application

A jaw coupling is a type of power transmission used in electric motors, compressors, pumps, and other industrial machinery. These couplings provide a quick and easy method of connecting or disconnecting shafts and can operate over a wide temperature range.

When selecting a jaw coupling, it is important to consider its torque rating. This is the maximum torque that the coupling can transmit. The amount of angular misalignment can also be tolerated along the axial dimension.

A jaw coupling is not well suited for precise movement, but it is strong and has adequate damping capabilities. Plus, it’s accurate at rest. With enough noise, it can alert the operator when something is wrong.

Jaw couplings are widely used in large industrial machines such as compressors, mixers, and blowers. They are also used in smaller motion control systems. While they are not ideal for precision movements, they have good vibration absorption and are often inexpensive.

Medical Instruments

Aviation Sector