Product Description

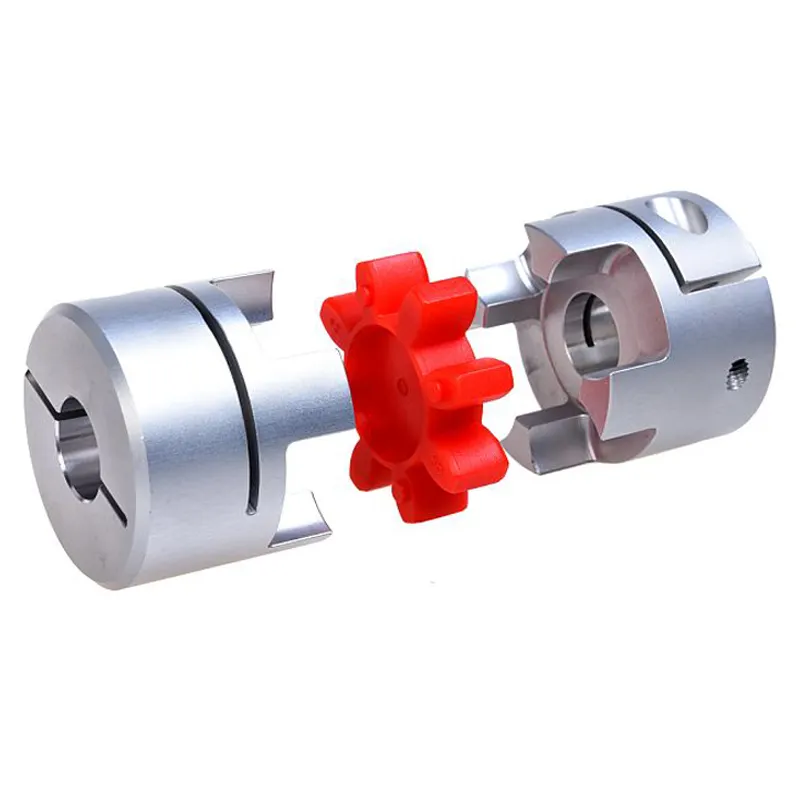

Ynf Excavator Spare Parts Rubber Jaw Spider Coupling Red Gr75 160*80-37

Structure:Jaw / Spider Flexible or Rigid:Flexible

Standard or Nonstandard:Standard Material:PU, or others, PU

Brand Name:Y&F Place of Origin:HangZhou, China (Mainland)

Model Number:Elastic spider Item:spider coupling rubber

Color:Red color Size:GR75

MOQ:1 Pcs, also depend on you needs Specification:160*80*37

Supply Ability

Supply Ability:

3000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

In standard export packing:suche as carton, plastic bags etc.

HangZhou,China

Lead Time :

In 3-7 days or according to your orders

|

Place of Origin |

HangZhou, China (Mainland) |

|

Brand Name |

YNF/Y&F |

|

Property |

High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

|

Shape |

According to your requirement. |

|

Color |

Red color |

|

Material |

Jaw,Spider,Rubber |

|

Delivery |

Within 10 days after payment |

|

Packing |

Plastic bag & carton box or according to your requirements. |

|

Application |

Excavator/Digger |

Product show as below:

|

OD |

ID | H | |

| GR-28 | 65 | 30 | 20 |

| GR-38 | 80 | 38 | 22 |

| GR-42 | 95 | 45 | 20 |

| GR-48 | 105 | 52 | 26 |

| GR-55 | 120 | 60 | 27 |

| GR-65 | 134 | 69 | 25 |

| GR-75 | 160 | 80 | 37 |

| GR-90 | 199 | 100 | 42 |

| GR-100 | 224 | 113 | 38 |

| GR-110 | 225 | 127 | 42.5 |

About us:

Company Information

Yingfeng Construction Machinery Limited established in 1988,having both trading company and owned factory .Office and showroom are located in HangZhou ,Xihu (West Lake) Dis. district. We produce and sell various Excavator Parts,such as coupling,Oil Seal,Hydraulic Parts,Excavator Rubber Parts,Excavator Electric Parts,Excavator wearing Parts,Engine Parts,Excavator Filters,Excavator Gears,Bearings,Excavator A/C Parts,Excavator Undercarriage Parts and Some air compressor couplings.

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Using Jaw Couplings in Hydraulic and Pneumatic Systems

Yes, jaw couplings can be used in both hydraulic and pneumatic systems to connect the driving and driven components. Jaw couplings are versatile and well-suited for various power transmission applications, including those involving fluid-based systems. Here’s how jaw couplings are compatible with hydraulic and pneumatic systems:

- Flexibility: Jaw couplings are made of flexible materials, such as elastomers, which allow for some angular, parallel, and axial misalignment between the shafts. In hydraulic and pneumatic systems, where vibrations and movements are common, the jaw coupling’s ability to accommodate misalignment helps reduce stress on the connected components.

- Shock Absorption: Hydraulic systems often experience pressure surges and hydraulic shocks due to rapid changes in fluid flow. Similarly, pneumatic systems may encounter air pressure fluctuations. Jaw couplings can absorb shocks and vibrations, protecting the system from sudden jolts and minimizing wear on components.

- Corrosion Resistance: Some jaw couplings are available in materials that offer excellent corrosion resistance, making them suitable for hydraulic systems working with hydraulic fluids and pneumatic systems handling compressed air, which may contain moisture.

- Low Inertia: Jaw couplings have low inertia, which is advantageous in applications where quick start-stop responses are required. This characteristic is beneficial in hydraulic and pneumatic systems that need rapid and precise movements.

- Backlash Prevention: Backlash, which can lead to vibrations and inaccuracies, is minimized with jaw couplings. This feature is beneficial in hydraulic and pneumatic systems where precise positioning is crucial.

- Simple Installation: Jaw couplings are easy to install and require minimal maintenance, making them suitable for various hydraulic and pneumatic applications.

- Compatibility with Shaft Sizes: Jaw couplings are available in different sizes and configurations, allowing for compatibility with various shaft diameters commonly found in hydraulic and pneumatic systems.

Overall, jaw couplings offer reliable power transmission in hydraulic and pneumatic systems, providing benefits such as flexibility, shock absorption, corrosion resistance, low inertia, and backlash prevention. However, it’s essential to consider factors such as operating conditions, temperature, and the type of fluid used when selecting a jaw coupling for a specific hydraulic or pneumatic application.

What are the temperature and environmental limitations of jaw couplings?

Jaw couplings, like many mechanical components, have temperature and environmental limitations that need to be considered for proper operation and longevity. These limitations are determined by the materials used in the construction of the jaw coupling and the specific operating conditions it will encounter. Here are some of the common temperature and environmental limitations of jaw couplings:

- Temperature Limitations: The operating temperature range of a jaw coupling depends on the materials used for its components, particularly the elastomer spider. Standard elastomers, such as polyurethane or nitrile rubber, are commonly used in jaw couplings and have typical temperature limits of approximately -40°C to 80°C (-40°F to 176°F). For more extreme temperature requirements, specialized elastomers with higher or lower temperature resistance may be available. It is essential to consider the ambient temperature and the temperature generated during equipment operation to ensure the jaw coupling remains within its temperature limits.

- Environmental Limitations: Jaw couplings can be affected by various environmental factors, and their performance might be influenced by the presence of certain substances. Some environmental limitations to consider include:

- Chemical Exposure: Exposure to harsh chemicals, oils, solvents, or corrosive substances can degrade the elastomer spider and other components of the jaw coupling. Specialized coatings or alternative materials may be required for applications with aggressive chemical environments.

- Dust and Debris: Excessive dust, dirt, or debris in the operating environment can accumulate on the coupling’s surfaces and affect its performance. Regular cleaning and maintenance may be necessary to prevent buildup and ensure optimal operation.

- Moisture and Water: Some jaw couplings may not be suitable for applications where they are continually exposed to moisture or submerged in water. In such cases, water-resistant or corrosion-resistant materials may be necessary.

- Shock and Vibration: High levels of shock and vibration in the operating environment can accelerate wear and reduce the coupling’s lifespan. Selecting a robust coupling design and appropriate materials can help mitigate the effects of these factors.

- Electrically Conductive Environments: In some applications, it is essential to consider the electrical conductivity of the coupling’s materials, especially when dealing with sensitive electronic equipment.

It is crucial to consult the manufacturer’s specifications and guidelines to ensure that the selected jaw coupling is suitable for the specific temperature and environmental conditions of the intended application. Proper maintenance, periodic inspections, and adhering to recommended operating parameters can extend the life and performance of the jaw coupling in a given environment.

Handling Misalignment with Jaw Couplings

Jaw couplings are designed to handle certain degrees of misalignment between shafts. They are flexible couplings that can accommodate both angular and radial misalignment to some extent. The elastomeric element in the jaw coupling provides the necessary flexibility to compensate for misalignment while transmitting torque between the shafts.

Angular Misalignment: Jaw couplings can handle small amounts of angular misalignment, typically up to a few degrees. However, excessive angular misalignment should be avoided as it can lead to increased wear on the coupling and connected equipment.

Radial Misalignment: Similar to angular misalignment, jaw couplings can also tolerate small amounts of radial misalignment. The elastomeric material allows the coupling to flex and adjust to minor shaft misalignments.

It’s important to note that while jaw couplings are suitable for handling some degree of misalignment, the actual allowable misalignment depends on the specific design and material of the coupling. Therefore, it is essential to refer to the manufacturer’s specifications and guidelines for the particular jaw coupling being used in an application.

For applications with significant misalignment or where precise alignment is critical, other types of flexible couplings, such as beam couplings or disc couplings, may be more appropriate. Proper alignment and regular maintenance are key factors in ensuring the optimal performance and longevity of the jaw coupling and the connected machinery.

editor by CX 2024-04-26