Product Description

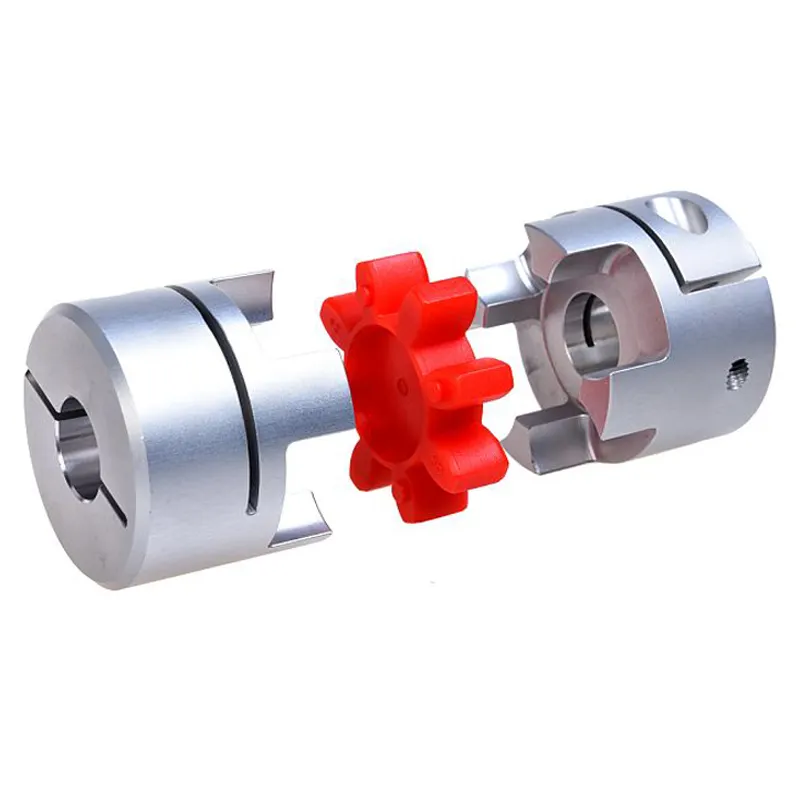

L type jaw coupling three-jaw elastic coupling

Description of L type jaw coupling three-jaw elastic coupling

>Zero rotation clearance, suitable for CHINAMFG and reverse rotation

>The colloid is made of polyurethane and has good wear resistance

>Oil resistance and electrical insulation, intermediate elastomer can absorb vibration

>Compensation for radial, angular and axial deviations

>Detachable design, easy to install

Dimensions of L type jaw coupling three-jaw elastic coupling

Impact of Jaw Coupling on Noise and Vibration in Mechanical Systems

Jaw couplings play a significant role in mitigating noise and vibration levels in mechanical systems. The design and materials of the coupling determine its ability to dampen vibrations and reduce noise. Here’s how a jaw coupling affects noise and vibration in a mechanical system:

- Vibration Dampening: Jaw couplings, especially elastomer jaw couplings, are designed to absorb and dampen vibrations that may occur in the system. The elastomeric spider element in elastomer jaw couplings acts as a cushion, absorbing shocks and vibrations that might result from misalignment, sudden starts, or stops. By absorbing vibrations, jaw couplings help prevent these vibrations from propagating through the system, thus reducing the overall vibration levels.

- Noise Reduction: The vibration dampening properties of jaw couplings also contribute to noise reduction. Vibrations can lead to mechanical noise, which can be particularly pronounced in high-speed applications. By reducing vibrations, jaw couplings help decrease the noise generated during system operation. This is especially beneficial in applications where low noise levels are crucial for the comfort of operators or nearby occupants.

- Misalignment Compensation: Jaw couplings are designed to accommodate a certain degree of misalignment between the shafts they connect. This ability to compensate for misalignment prevents additional forces and stresses from being transferred to the system, reducing the likelihood of generating noise and vibrations due to misalignment.

- Material Selection: The choice of materials in jaw couplings can also influence noise and vibration levels. Elastomer jaw couplings, with their flexible spider element, offer superior vibration dampening compared to rigid metallic jaw couplings. Metallic jaw couplings, while not as effective at vibration dampening, are more rigid and offer higher torque capacity.

Overall, jaw couplings are effective in reducing noise and vibration levels in mechanical systems. The extent of noise and vibration reduction depends on the specific design, material, and the level of misalignment the coupling can accommodate. Properly selected and installed jaw couplings can contribute to a smoother and quieter operation of the entire mechanical system.

What are the common installation mistakes to avoid when using jaw couplings?

Proper installation of jaw couplings is crucial to ensure their reliable and efficient operation. Avoiding common installation mistakes can prevent premature wear, misalignment, and potential equipment damage. Here are some of the most common installation mistakes to avoid when using jaw couplings:

- Incorrect Coupling Size: Using the wrong size of jaw coupling for the application can lead to various issues. Undersized couplings may not handle the required torque, leading to early failure, while oversized couplings may result in increased rotational inertia and decreased system performance. Always ensure that the selected coupling is appropriate for the torque and power requirements of the equipment.

- Misalignment: Improper alignment of the shafts during coupling installation can cause excessive forces and premature wear on the coupling components. Angular, parallel, and axial misalignments should be minimized and kept within the manufacturer’s recommended tolerances. Consider using alignment tools and techniques to achieve accurate shaft alignment.

- Over-Tightening: Applying excessive torque when tightening the coupling elements can lead to deformation of the elastomer spider or damage to the hubs. Over-tightening can also increase friction and cause premature wear. Follow the manufacturer’s specified torque values during installation to ensure proper clamping without causing damage.

- Lack of Lubrication: Some jaw couplings require lubrication to reduce friction and wear. Neglecting to lubricate the coupling elements can lead to increased friction, higher operating temperatures, and reduced coupling life. Follow the manufacturer’s guidelines regarding lubrication intervals and types of lubricants to use.

- Failure to Inspect Components: Before installation, carefully inspect all coupling components for any signs of damage, wear, or defects. Using a damaged or worn-out elastomer spider or other components can compromise the coupling’s performance and reliability. Replace any worn or damaged parts before installing the coupling.

- Improper Shaft End Preparation: Ensure that the shaft ends are clean, smooth, and free from burrs or imperfections before installing the coupling. Rough or uneven shaft surfaces can lead to misalignment and reduce coupling performance. Properly clean and prepare the shaft ends to ensure a secure and accurate fit.

- Not Following Manufacturer’s Guidelines: Each jaw coupling has specific installation instructions provided by the manufacturer. Failure to follow these guidelines can result in coupling failure or reduced performance. Always refer to the manufacturer’s installation manual and recommendations for proper installation procedures.

By avoiding these common installation mistakes, users can maximize the performance and longevity of jaw couplings in their applications. Proper installation ensures that the coupling operates efficiently, transmits power effectively, and reduces the risk of unexpected failures or downtime.

Limitations and Disadvantages of Using Jaw Couplings

While jaw couplings offer several advantages, they also have some limitations and disadvantages that should be considered when selecting them for specific applications:

- Angular Misalignment: Jaw couplings are sensitive to angular misalignment, and excessive misalignment can lead to increased wear and reduced service life.

- Radial Misalignment: Similar to angular misalignment, radial misalignment should be kept within acceptable limits to prevent premature wear.

- Temperature Limitations: The operating temperature range of jaw couplings may be limited by the material used. For high-temperature applications, other coupling types may be more suitable.

- Shock Load Absorption: While jaw couplings can handle moderate shock loads, they may not be ideal for applications with severe shock loads, which can lead to increased stress and failure.

- Torsional Stiffness: Jaw couplings have a certain level of torsional stiffness, which means they may not provide the same level of vibration isolation as other coupling types.

- Backlash: Jaw couplings can have some degree of backlash due to their elastomeric element, which may not be desirable in precision positioning applications.

- Speed Limitations: High-speed applications may require careful consideration of the jaw coupling’s design and material selection to avoid issues related to centrifugal forces.

Despite these limitations, jaw couplings remain a popular choice in many applications due to their ease of installation, simple design, and cost-effectiveness. Proper selection, installation, and maintenance can help mitigate some of these limitations and ensure optimal performance and reliability of the jaw coupling.

editor by CX 2023-12-08